Co-reactive secures € 6.5 million in seed financing

The climate tech start-up Co-reactive from North Rhine-Westphalia, founded in 2024, has completed seed financing totaling €6.5 million. The company plans to use the capital to take its CO₂ mineralization technology from prototype to industrial application.

Funding from leading investors and subsidies

The financing round is led by High-Tech Gründerfonds (HTGF). Other investors include NRW.Bank, HBG Ventures, AFI Ventures (the early-stage impact arm of Ventech), Evercurious VC and a network of experienced climate-tech business angels. In addition, Co-reactive receives seven-figure funding from the Federal Ministry for Economic Affairs and Energy (BMWE)'s Bundesförderung Industrie und Klima (BIK).

The construction industry is at a turning point. Co-reactive offers a scalable alternative that is CO₂-negative and can be integrated into existing processes as a drop-in solution. The team has the potential to change the industry for good.

Anna Stetter, Investment Manager at HTGF

Innovative CO₂ mineralization technology

Co-reactive has developed a continuous process that converts CO₂ together with natural minerals such as olivine or metallurgical slags (EAF & BOF) into CO₂-negative Supplementary Cementitious Materials (SCMs). The materials significantly reduce the clinker content in cement and building materials, thus lowering the CO₂ footprint while improving compressive strength and durability. The technology is designed as a drop-in solution and can be seamlessly integrated into existing production processes.

Solutions for the construction industry

Co-reactive addresses two key challenges:

- High emissions: Cement production is responsible for around eight percent of global CO₂ emissions. With rising CO₂ prices, production costs could rise significantly in the coming years.

- Shortage of raw materials: traditional cement substitutes such as fly ash or granulated blast furnace slag are becoming scarce due to the coal phase-out and the transformation of the steel industry.

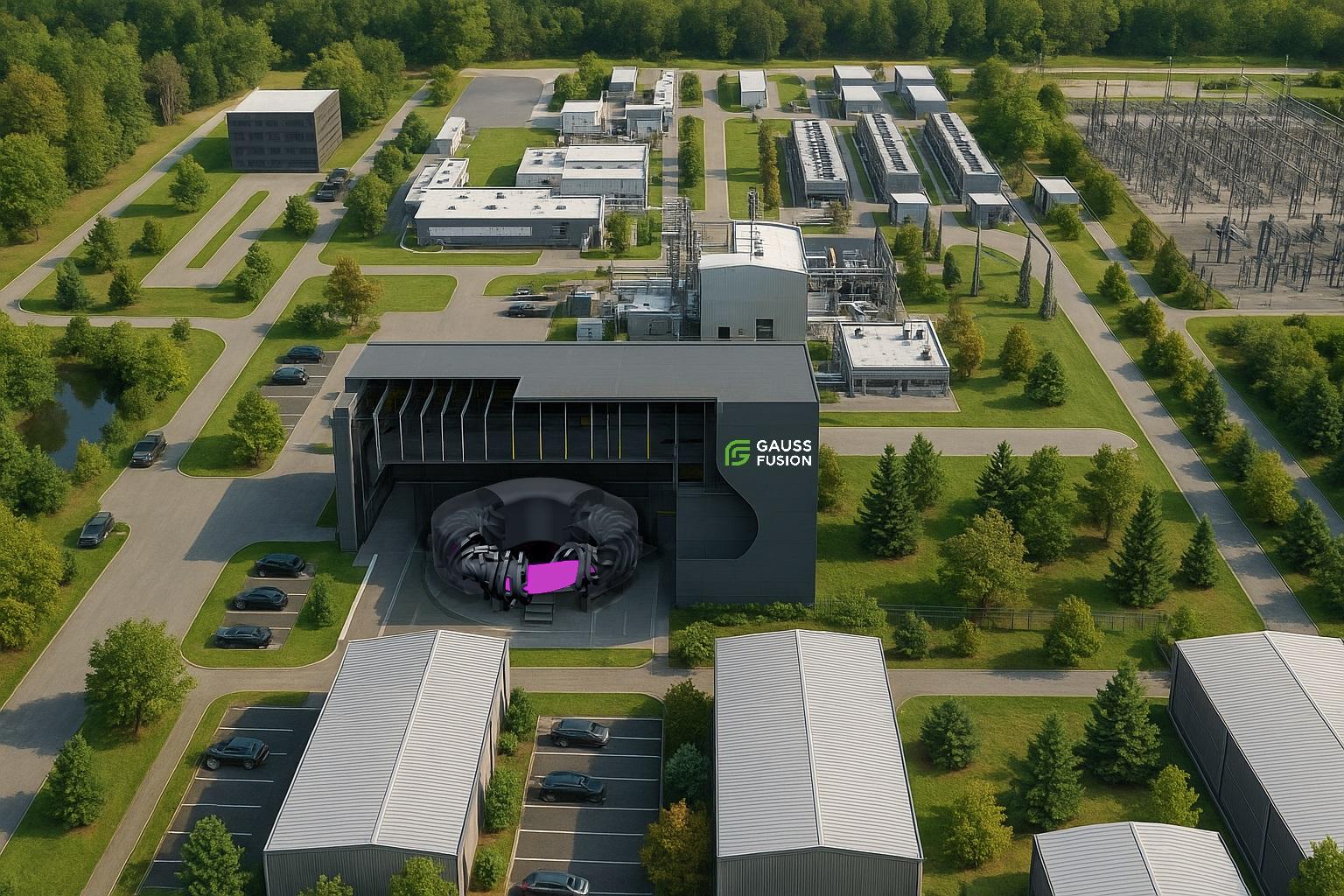

With the seed funding, Co-reactive will scale up its laboratory and pilot operations to a continuously operated 1,000-tonne demonstration plant in the second quarter of 2026. In parallel, pilot plants on a ten-thousand-tonne scale are being prepared together with industrial partners, which will mineralize CO₂ directly in cement and steel production from 2027.

With the right co-founders and an interdisciplinary team, we are taking CO₂ mineralization from the laboratory to continuous industrial operation.

Dr.-Ing. Andreas Bremen, co-founder and CEO of Co-reactive

Co-reactive GmbH develops continuous CO₂ mineralization technologies for the construction industry. The startup works along the entire value chain, from CO₂ and raw material suppliers to cement and concrete producers and certification bodies, to enable the transition from pilot to large-scale industrial plants on a 100- to 300-kt scale. The interdisciplinary team combines expertise in CO₂ mineralization, plant engineering and commercialization.

Newsletter

Startups, stories and stats from the German startup ecosystem straight to your inbox. Subscribe with 2 clicks. Noice.

LinkedIn ConnectFYI: English edition available

Hello my friend, have you been stranded on the German edition of Startbase? At least your browser tells us, that you do not speak German - so maybe you would like to switch to the English edition instead?

FYI: Deutsche Edition verfügbar

Hallo mein Freund, du befindest dich auf der Englischen Edition der Startbase und laut deinem Browser sprichst du eigentlich auch Deutsch. Magst du die Sprache wechseln?