Respiratory equipment

Early on in the outbreak of Covid-19, it became clear that ventilators were of great importance in saving lives. In Germany and the USA, there are approximately 90 to 120 ventilators per 100,000 people in hospital intensive care units. In Great Britain, Spain or France, there are sometimes only 30 to 40 devices per intensive care unit.

This acute shortage has had devastating consequences in recent weeks. Spain and Italy, for example, had Covid-19 patients airlifted to German hospitals because their ventilator capacities were exhausted. But in this country, too, fears of capacity exhaustion were running high.

To counteract shortages, the federal government ordered 10,000 ventilators from Draeger, a medical technology company based in Lübeck, Germany, in addition to the far-reaching lockdown measures. According to Draeger, however, production will drag on throughout the year.

So the search for alternatives and additional production possibilities continues.

The American way: let the auto industry produce masks

Initially, we assumed that the auto industry, which had been at a standstill for weeks, would be able to switch to producing respirators. So at the end of March, Donald Trump used a wartime law to force automakers General Motors and Volkswagen to produce respirators. Trump demanded production of 100,000 devices within 100 days.

But this proved to be of little use, with experts warning of the complexity and high safety requirements of medical technology.

"On a production line that makes cars, I can't just make ventilators," said Jean Haeffs, executive director of the Production and Logistics Society at the Association of German Engineers (VDI). The multitude of processes that differ, high demands on the safety of the devices as well as a high complexity of the systems make it impossible for companies from outside the industry to produce intensive medical devices. However, supporting production of individual parts using 3D printing would be conceivable.

Ventilation from the printer

The University Hospital Leipzig, the WHZ and the Frauenhofer IWU

show how this is possible. Together they developed a prototype for a 3D-printed emergency ventilator. Through interdisciplinary cooperation, it was possible to develop the first prototype within one week.The student Lukan Basan, who studies automotive engineering in the 4th semester at the WHZ, was significantly involved here. His mother works at the university as a laboratory engineer in the field of biomedical engineering and asked him if he would like to support this project. "3D printing is one of my main interests," says Lukas Basan about the beginnings of the family-interdisciplinary collaboration.

With that, his support was secured and together with a research team and numerous scientists, the foundation was laid and within a very short time, the 3D printed ventilator was developed.

The device is also not a medically certified ventilator, but it is an emergency option that could save the lives of many patients. Big advantage: Up to three of these systems can be printed per day and the development is slalable, so by having access to an international network of 3D printers, the systems could also be manufactured in large quantities in different countries.

From the gas wall heater to the ventilator

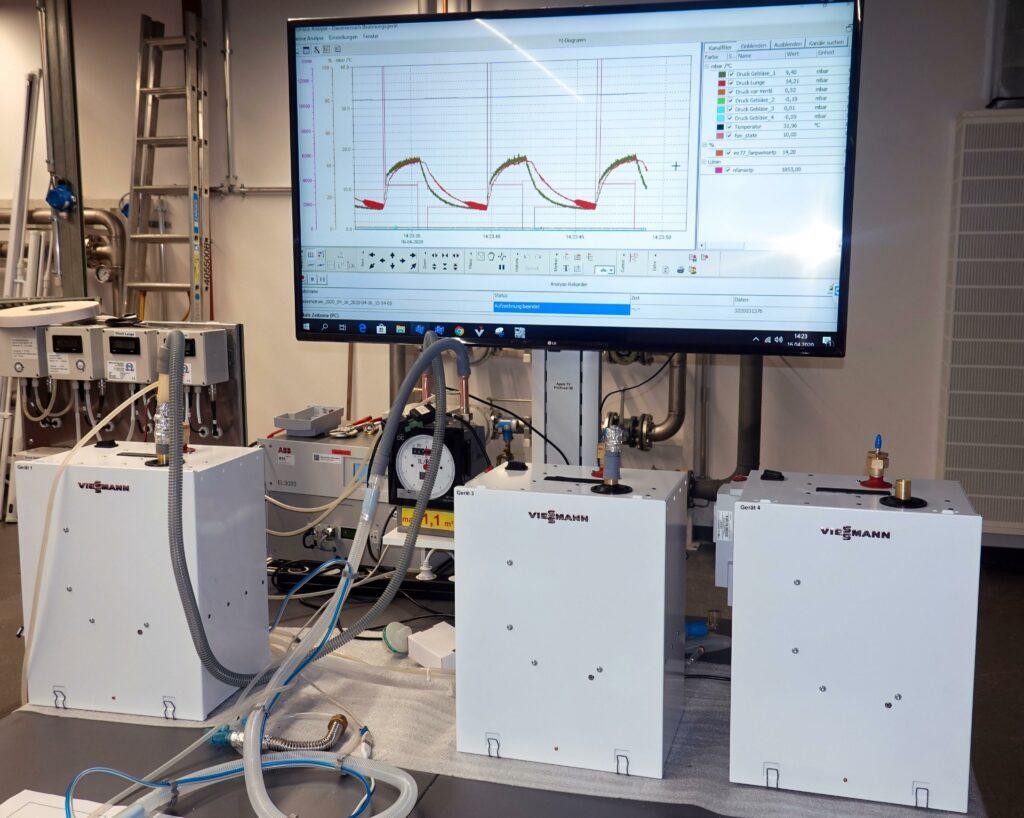

At the end of April, the heating equipment manufacturer Viessmann

announced that it was now switching parts of its production to the manufacture of respirators. Within three days the first prototype was developed and after three weeks the first device. This was "totally remarkable and an insane effort by everyone involved," Viessmann reported in its first major interview since the shutdown.

With great ambition, diligence and commitment of the developers and in close cooperation with physicians of the Luisenhospital

, the academic teaching hospital of the medical faculty of the RWTH Aachen, the development could be advanced so rapidly. This was supported by the fact that similar parts that are also required in ventilators are produced in the manufacture of gas wall devices.According to Viessmann, the simple ventilators are mobile and do not depend on the technical infrastructure of a hospital. However, they do not replace high-tech ventilators and should therefore only be used as a support when all ventilators are already in use.

But this is also an urgently needed support and the manufacturer gives hope, according to its own information, 600 ventilators per day can be produced after the special approval.

That was part #3 of our series "Pivot Masters."

In the next part, we turn our gaze to newly formed social initiatives that are fighting the consequences of the Corona Crisis.FYI: English edition available

Hello my friend, have you been stranded on the German edition of Startbase? At least your browser tells us, that you do not speak German - so maybe you would like to switch to the English edition instead?

FYI: Deutsche Edition verfügbar

Hallo mein Freund, du befindest dich auf der Englischen Edition der Startbase und laut deinem Browser sprichst du eigentlich auch Deutsch. Magst du die Sprache wechseln?