It's never too early for industrial design

In his industrial design and development office, he deals with the design and user-related qualities of customer products as well as their constructive development through to production. He shows how interdisciplinary development from the initial idea to production creates real added value - for start-ups and industrial projects alike.

When was the point in your life when you knew: "I'm going to be an industrial designer"?

When I was younger, I always wanted to be an inventor. I only found out later that there is no training to become an inventor. Over time, it became increasingly clear that the best way to pursue this goal was to study industrial design or mechanical engineering. After a few semesters of mechanical engineering, I finally got a competitive place on an industrial design course and switched. The engineering content remained - and the combination with industrial design is unbeatable. I started my own business 15 years ago and now run the Rojahn Design office in Berlin.

You have also worked with many start-ups. What is special about that?

I find it particularly exciting to be involved in the development of completely new concepts and am happy to contribute the experience we have gained in the office working with other start-ups and industrial clients. As start-ups are still at an early stage of development, we can provide targeted support during development, particularly when it comes to questions about manufacturing processes and the associated process steps, for example in design, construction, prototyping and toolmaking, and the expected processing times. In addition, many potential disasters can be avoided.

When is a good time for start-ups to incorporate industrial design into development?

One example is the collaboration with Cobra Products in the development of their Cable Cobra product (www.cablecobra.de). This is a practical and robust holder for electric car charging cables - the Cobra prevents the cable from touching the ground when charging. The founders had initially tested functional models and planned to manufacture the entire product from plastic using injection molding. However, I was able to demonstrate that the central component could be manufactured much more effectively from sheet metal. All that remained was a simple plastic part. This not only significantly reduced the initial investment, as the complex geometry made of plastic would have required expensive tools; the reduced number of parts also made assembly much easier. At the same time, the product became much more robust and of higher quality.

If you only get involved at a late stage, a course correction is much more difficult and often leads to avoidable time losses. In Berlin, there are also funding programs whose application requires some lead time before you can even start with the actual work. So there is no such thing as "too early", as the intensity of the collaboration can be increased as required and you don't have to start at 100% straight away.

Your experience ranges from medical technology to satellite production. How varied are your areas of responsibility?

My office mainly works in the field of capital goods - from laboratory equipment to machine controls and train electronics to mobility solutions. One characteristic that these products often have in common is their longevity - and this is also reflected in the design.

Many projects require familiarization with very different subject areas. That's why we don't limit ourselves strictly to a single area and are happy to take on new challenges.

You are very familiar with manufacturing processes - would you say this is a "must" as an industrial designer?

It is extremely valuable to have an overview of the possibilities and limitations of the relevant manufacturing processes right from the start of a project in order to be able to work efficiently and purposefully. With the office, we develop for series production - for this, it is crucial to know the planned quantities, because ultimately it's all about cost-effectiveness. Every good or bad decision makes itself felt many times over in series production. If you accompany or are responsible for a project from the first sketch to the final production data, this is undoubtedly a great advantage for the process and the result. For me, this is a matter of course - and our customers appreciate it.

What has been your biggest project so far?

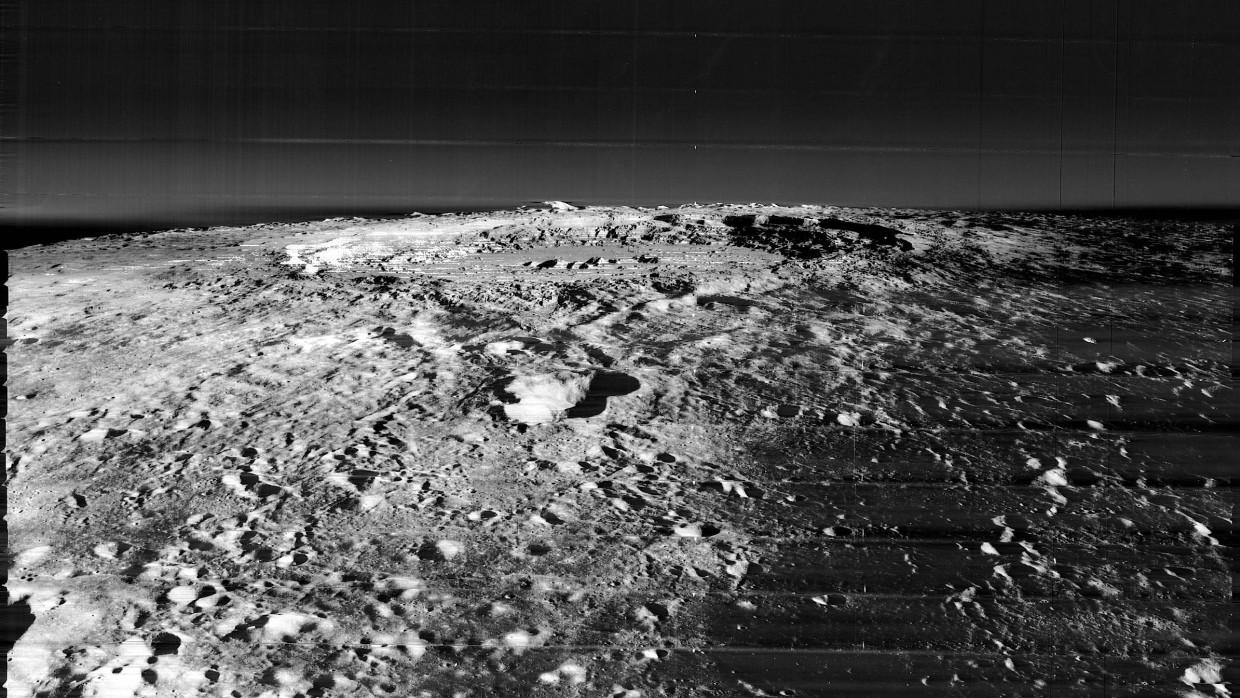

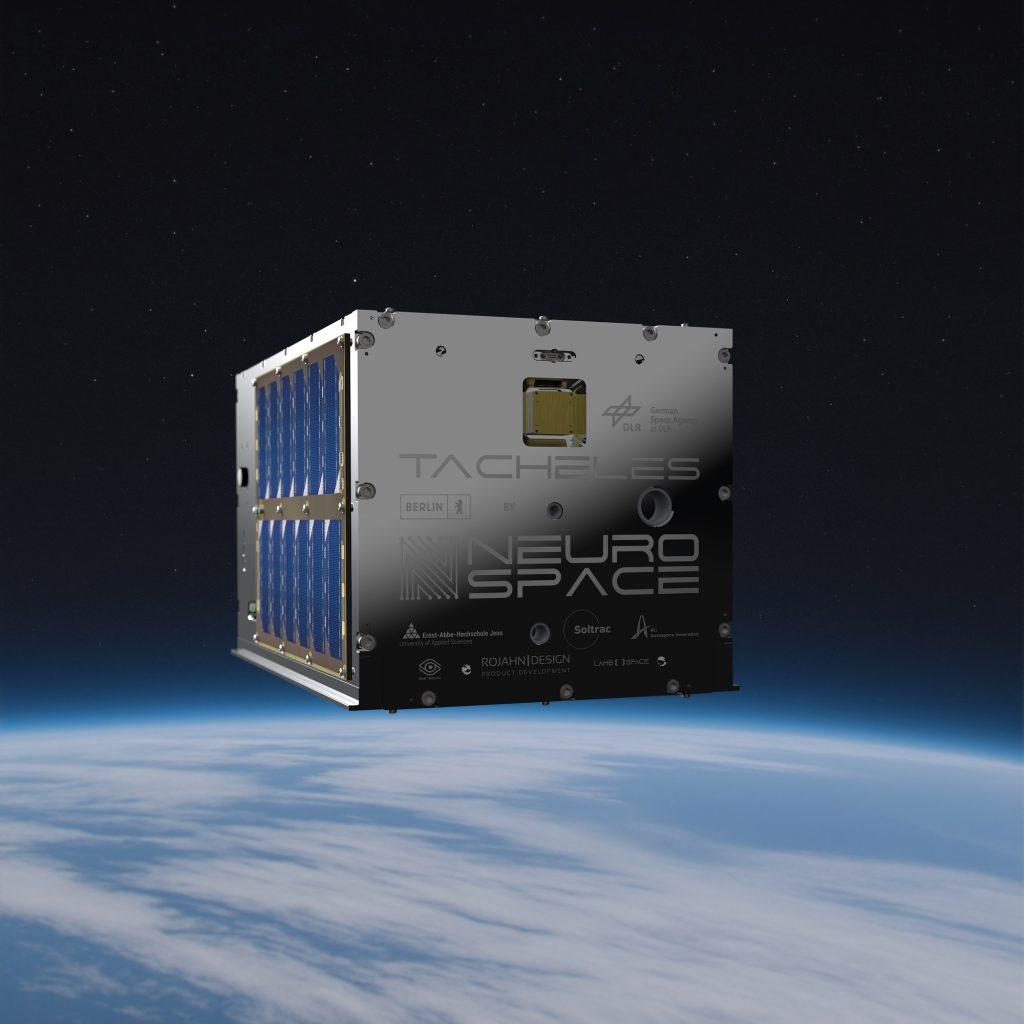

I became a partner in the new space company NEUROSPACE by working with start-ups. We develop moon rovers. We are currently the only selected European company that is carrying its own satellite on NASA's Artemis II mission - the first manned moon mission since Apollo around 50 years ago. Our satellite called "TACHELES", which we use to test system components of the rovers, was recently handed over to NASA at the Kennedy Space Center. This was the largest project to date - funded by the German Federal Ministry for Economic Affairs and Climate Protection. A short pitch at this point: whether financially or professionally - we still have places for fellow travelers!

Do you have a project in which your interdisciplinary approach came to the fore?

Rojahn Design is responsible for both the industrial design and the construction of the housing: from the graphic design of the front, which structures the operating elements, to the three-dimensional design of the back of the housing, including the production data. Not only functional and aesthetic considerations played a role here, but also the simplest and most cost-efficient production possible in large quantities. Many design and construction decisions have a direct impact on tooling and parts costs as well as assembly costs. In order to develop a highly competitive product, we have carefully analyzed and optimized every aspect together with ARBURG.

Do you have an example that illustrates the connection between industrial design and corporate identity?

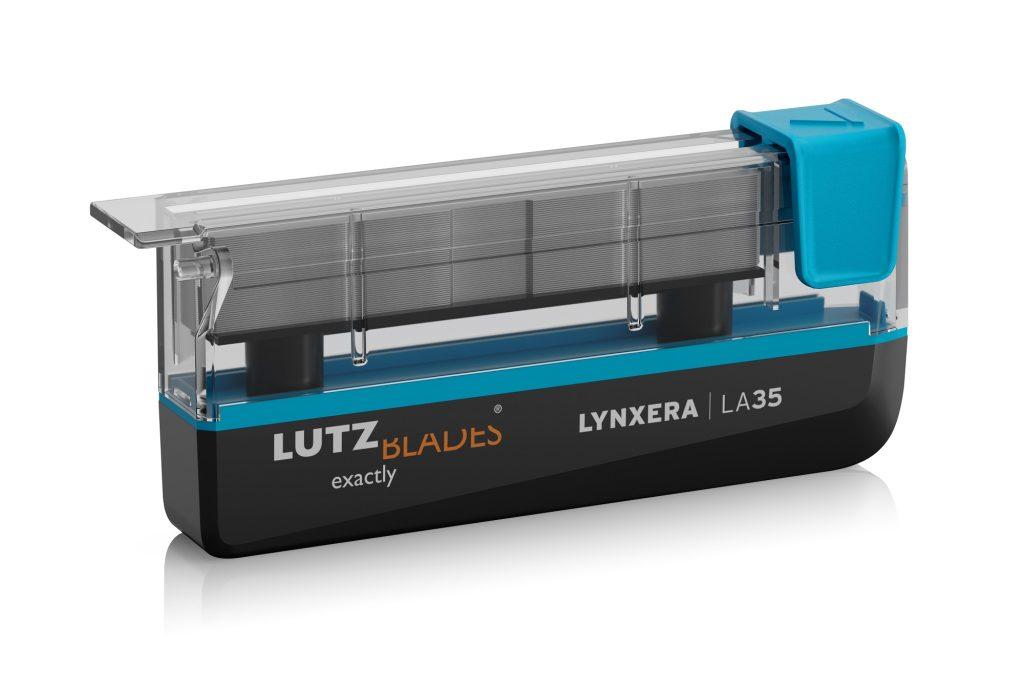

The Solingen-based blade specialist LUTZ BLADES approached the office with the plan to open up a new market for the company with microtome blades. This required a dispenser that not only enables safe and easy handling of the extremely sharp laboratory blades, but also gives the project a face. The dispenser makes the high quality of the blades tangible and is unmistakable.

What does sustainability mean for your work?

We value longevity - both on a functional and aesthetic level. Our aim is to create designs that still look modern years later. In doing so, we always strive for the greatest possible simplicity - which often leads naturally to more sustainable solutions. We are happy to suggest more environmentally friendly material alternatives to our customers. Ultimately, however, these decisions are not in our hands, even though the topic is very close to our hearts.

What advantages does it have for the development process that you act as an independent contractor with an outside perspective?

I keep hearing from our customers how valuable this is. We question the familiar, which is sometimes outdated, and provide impetus in directions that no one has seen before. Our own entrepreneurial perspective - both as a service provider and through the many insights into our customers' processes - is a great advantage. From my own everyday office life, I know how important the conscious use of resources is and that every decision can have an impact on the success of a product and a company.

Many thanks for the interview

We would like to thank Johannes Rojahn for the informative interview. Rojahn Design is based in Berlin - right in the heart of the vibrant start-up scene. You can find more insights into the work of Johannes Rojahn and his office on the website: https://rojahn-design.com/

Newsletter

Startups, stories and stats from the German startup ecosystem straight to your inbox. Subscribe with 2 clicks. Noice.

LinkedIn ConnectFYI: English edition available

Hello my friend, have you been stranded on the German edition of Startbase? At least your browser tells us, that you do not speak German - so maybe you would like to switch to the English edition instead?

FYI: Deutsche Edition verfügbar

Hallo mein Freund, du befindest dich auf der Englischen Edition der Startbase und laut deinem Browser sprichst du eigentlich auch Deutsch. Magst du die Sprache wechseln?